Razor blades play a vital role in the manufacturing process for catheter production, specifically in the preparation of catheter tubing. Their precise and efficient cutting capabilities play a crucial role in achieving accurate catheter dimensions.

Catheters are thin, flexible tubes used for a range of medical procedures, such as drainage, fluid delivery, and accessing blood vessels. The manufacturing process involves several stages, including extrusion, tip formation, and assembly. Razor blades are commonly employed during the cutting and trimming steps to achieve the desired catheter length and create smooth, even edges.

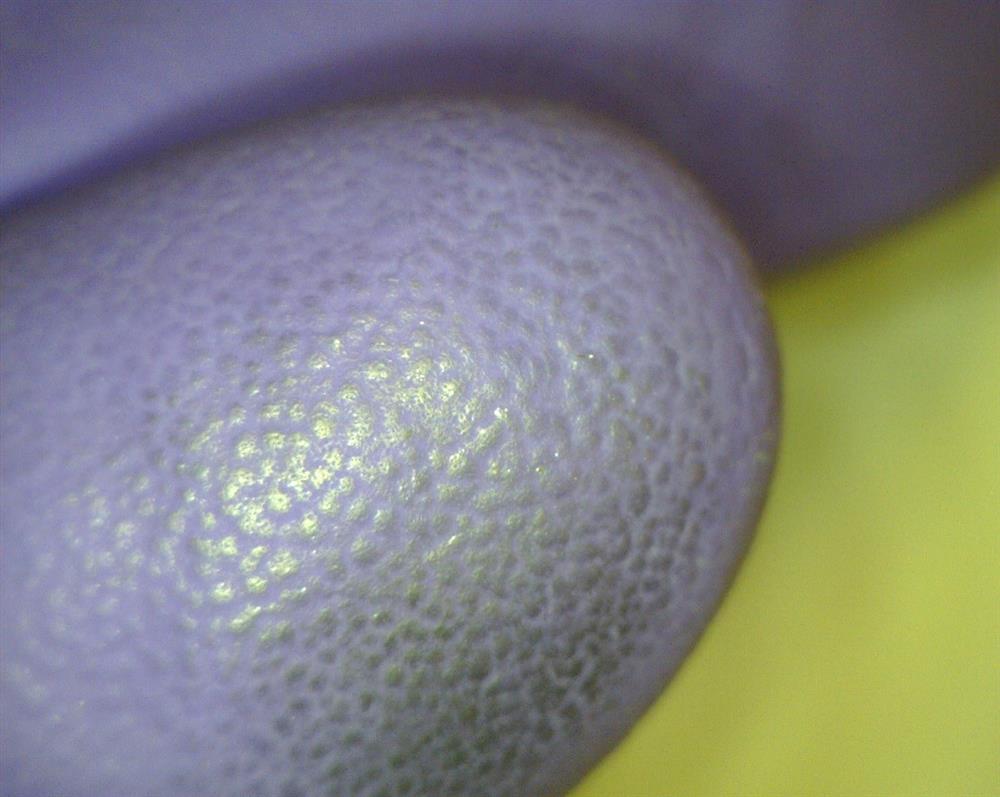

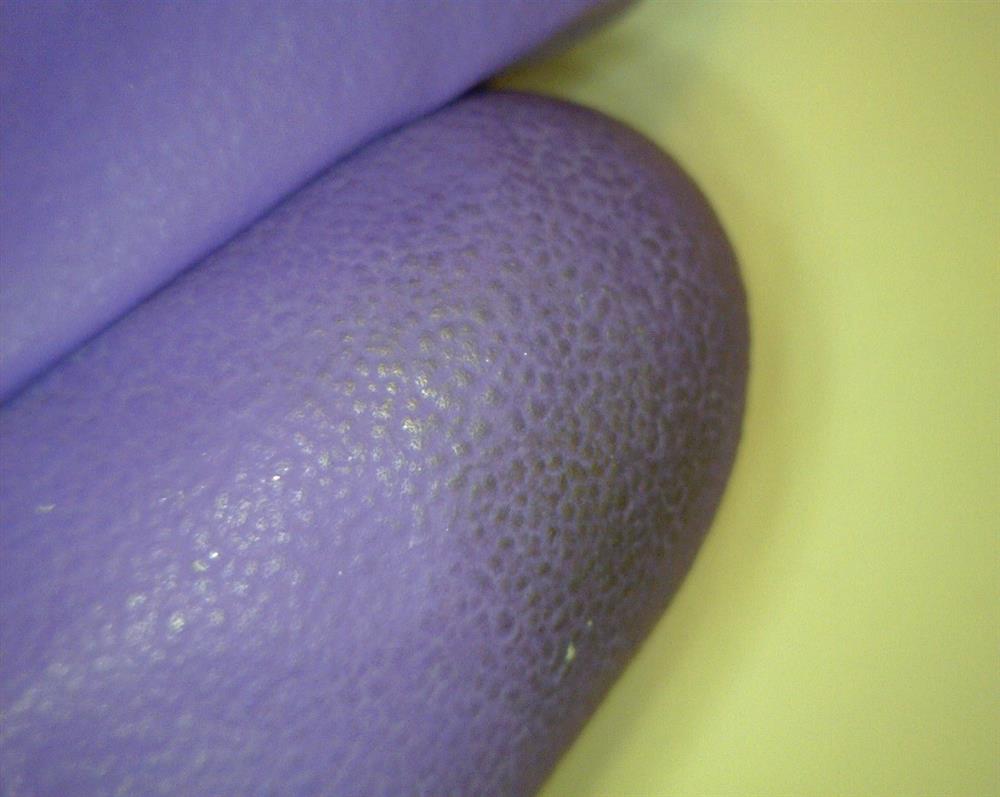

In the extrusion stage, a thermoplastic material, such as polyurethane or silicone, is forced through a die to create a long, continuous tube. Once the tube is extruded, it needs to be cut into individual catheter lengths. Razor blades, typically mounted on cutting equipment, are used to precisely and cleanly slice the extruded tube into specific lengths. The sharpness and precision of the blades ensure accurate and consistent dimensions across multiple catheters, which is critical for maintaining quality standards.

After cutting the catheter tube into individual lengths, razor blades may also be utilized to trim excess material or create specific shapes at the catheter tip. This step is crucial for specialized catheters, such as angioplasty or guiding catheters, where precise tip geometry is necessary for optimal performance during medical procedures.

Razor blades offer several advantages in the catheter manufacturing process. Firstly, their sharpness ensures clean and accurate cuts, minimizing the need for additional finishing processes. This efficiency contributes to higher production rates and overall cost-effectiveness. Additionally, razor blades are readily available and relatively inexpensive compared to other cutting tools, making them a practical choice for large-scale catheter production.

It is important to note that the use of razor blades in the catheter manufacturing process requires adherence to strict quality control and safety measures. Manufacturers must ensure the blades are properly installed, regularly inspected for wear or damage, and replaced when necessary to maintain consistent cutting performance and prevent any potential contamination risks.

In conclusion, razor blades are indispensable tools in the manufacturing process for catheters. Their precise cutting capabilities enable the accurate sizing and shaping of catheter tubing, contributing to the overall quality and functionality of the medical devices. As the medical industry continues to advance, razor blades will remain essential in the production of catheters, facilitating the creation of reliable and effective tools for various medical procedures.