A highly innovative medical device manufacturer is currently experiencing an issue with the standard (non-cleanroom approved) single edge razor blades shown below:

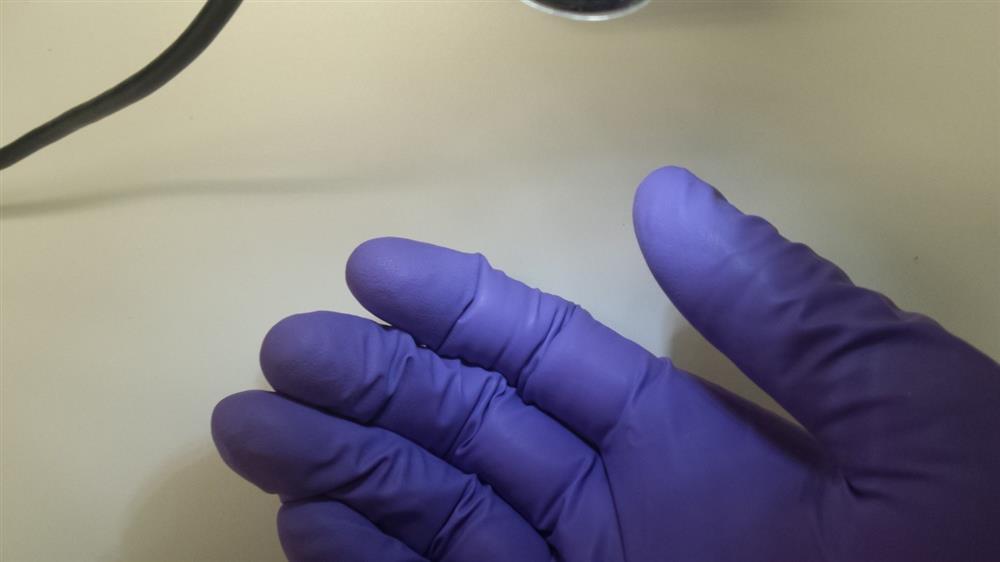

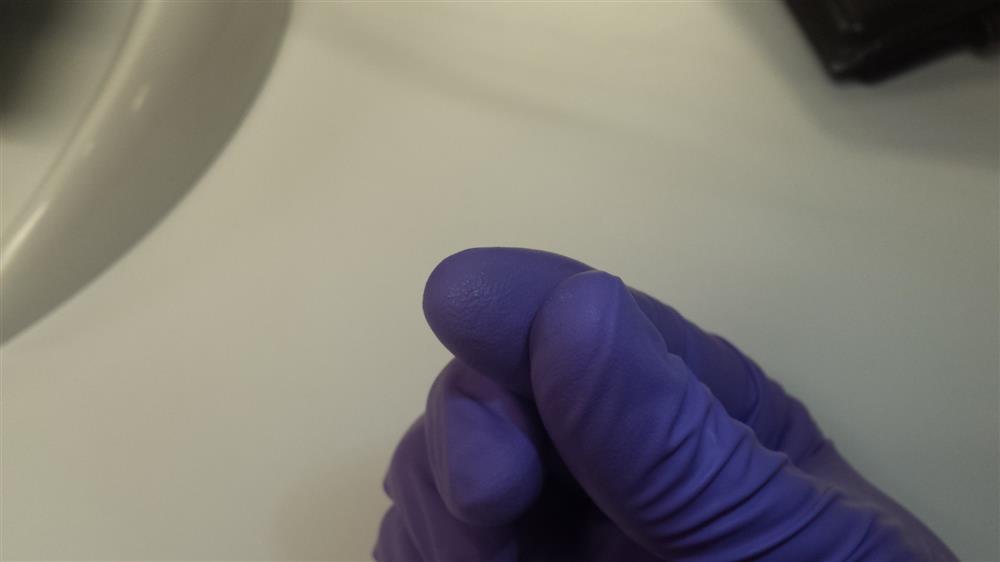

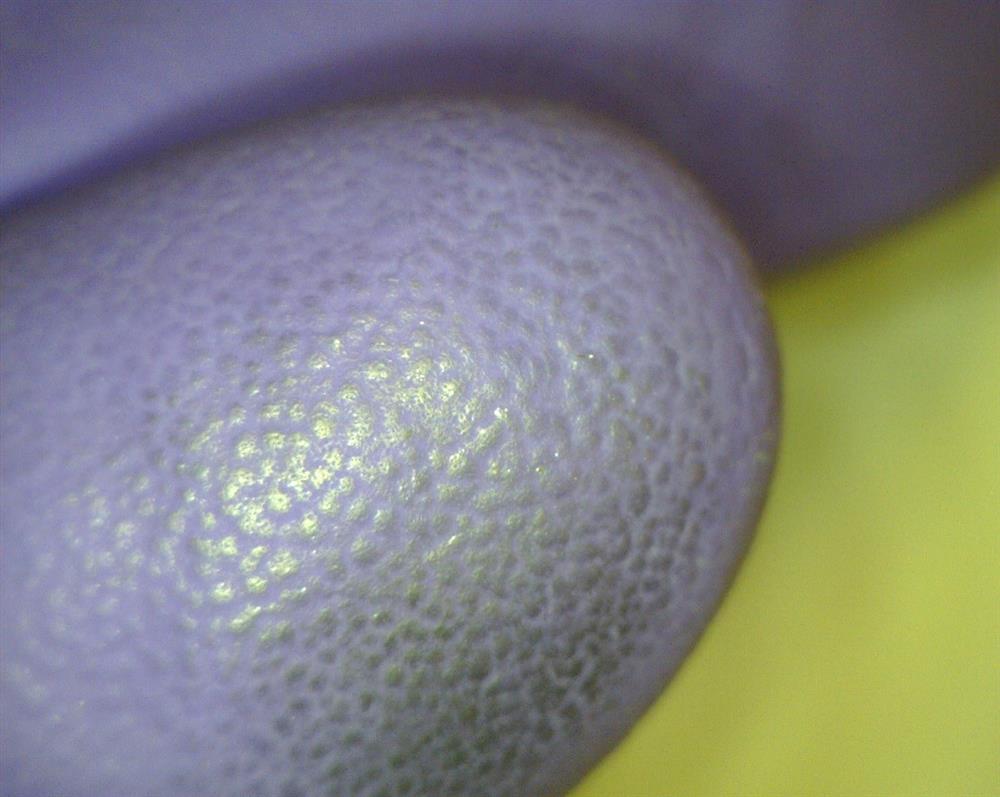

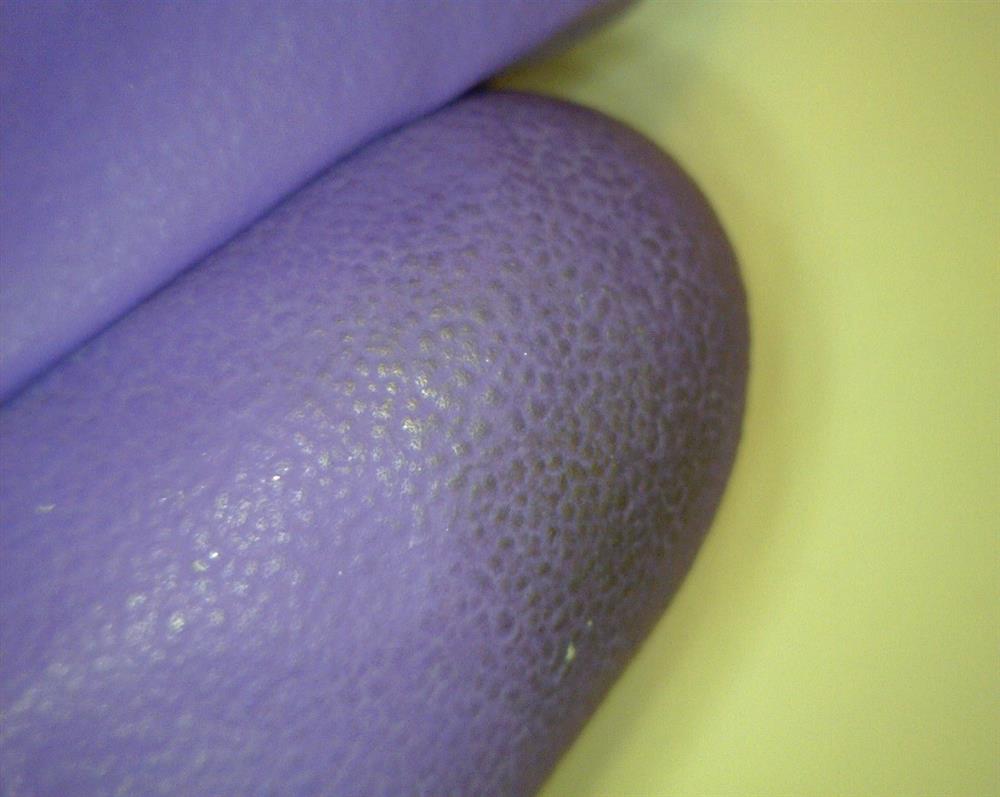

Upon handling the razor blades, particulate is being transferred from the blade to the operators’ gloves. See below:

Glove Prior to Handling Razor Blade

Magnified Image of Glove Prior to Handling Razor Blade

Glove after Handling Razor Blade, Metallic Particulate Present on Finger Tips

Magnified Image of Glove after Handling Razor Blade

The images shown above are after handling a single razor blade. The next images shown below are after handling several razor blades.

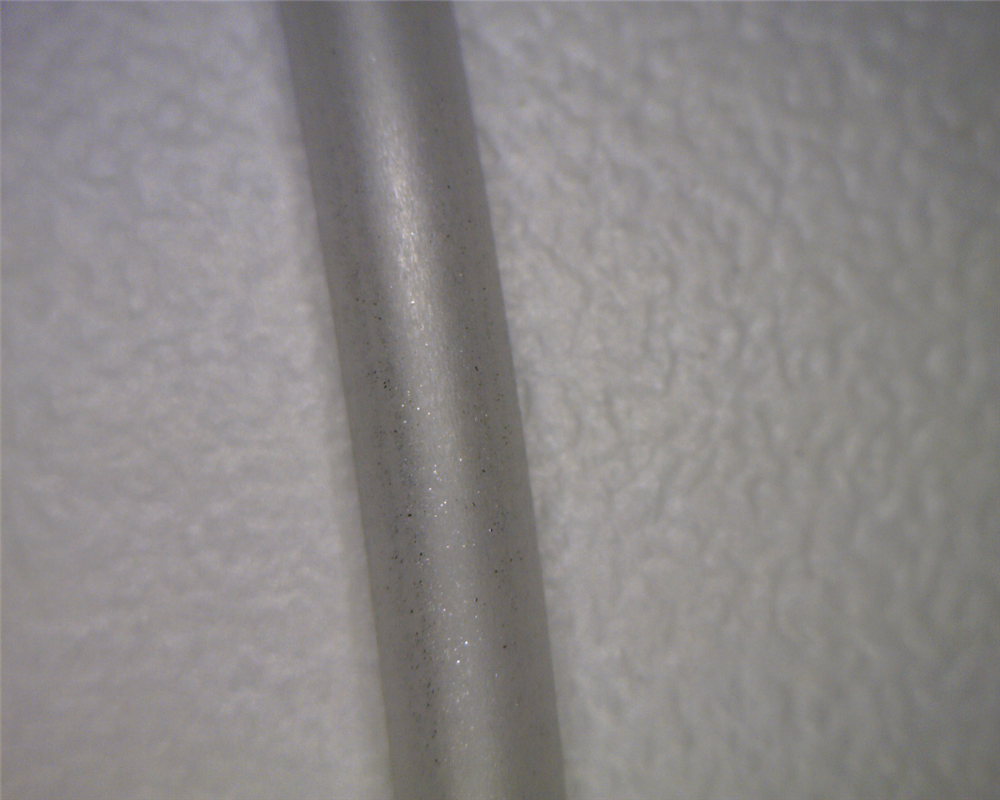

For the manufacturer's processes, the razor blades are used by operators who also come into contact with plastic tubing. See below:

Once the operators have the metallic particulates on their gloves, it can be transferred to the tubing.

Additionally, a razor blade was wiped using IPA and a lint free cloth. The contaminant removed is shown below:

The medical manufacturer is accustomed to seeing some degree of particulate from single edge razor blades. However, it has become much more present. To the point where they are experiencing high yield loss (>25%) on certain lots of product.

The innovative manufacturer overcame this challenge with the GEM Runner Product Line. A one of a kind system, the GEM Runner is a re-loadable safety dispenser paired with clean room grade washed and degreased single edge blades. The results proved to achieve ultra-high levels of cleanliness while reducing waste and hand injury.